- Use cases: IoT, Gen AI

- Industries: Manufacturing and Mobility

- Products and tools: Atlas, Time Series, Atlas App Services, Triggers, Functions, Device Sync

Build a virtual factory with MongoDB Atlas

_Spot (1).png?auto=format%252Ccompress)

Solution Overview

In today’s rapidly evolving manufacturing landscape, digital twins of factory processes have emerged as a game-changing technology. Digital twins serve as virtual replicas of physical manufacturing processes, allowing organizations to simulate and analyze their operations in a virtual environment. By incorporating artificial intelligence and machine learning, organizations can interpret and classify objects, leading to cost reductions, faster throughput speeds, and improved quality levels. Real-time data, especially inventory information, plays a crucial role in these virtual factories, providing up-to-the-minute insights for accurate simulations and dynamic adjustments.

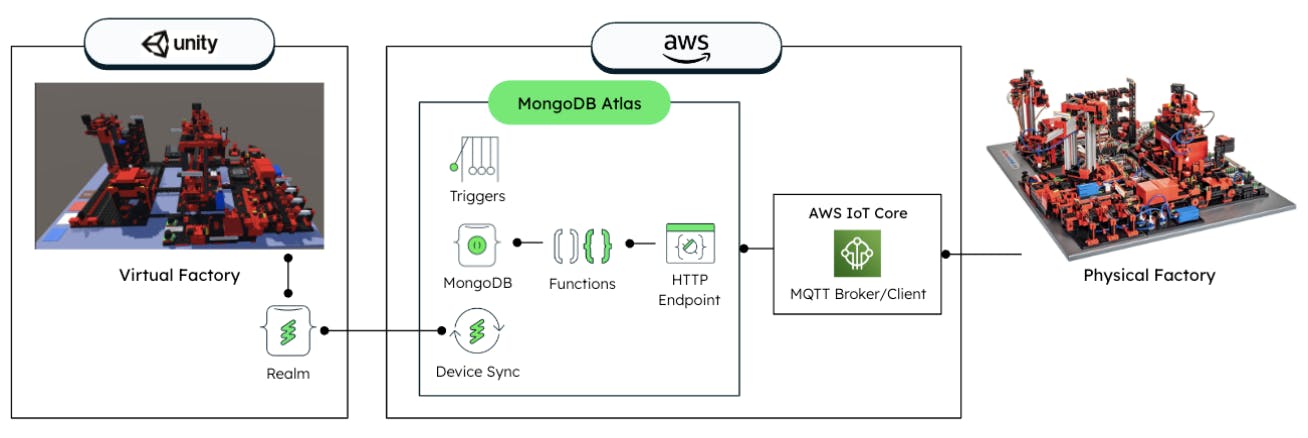

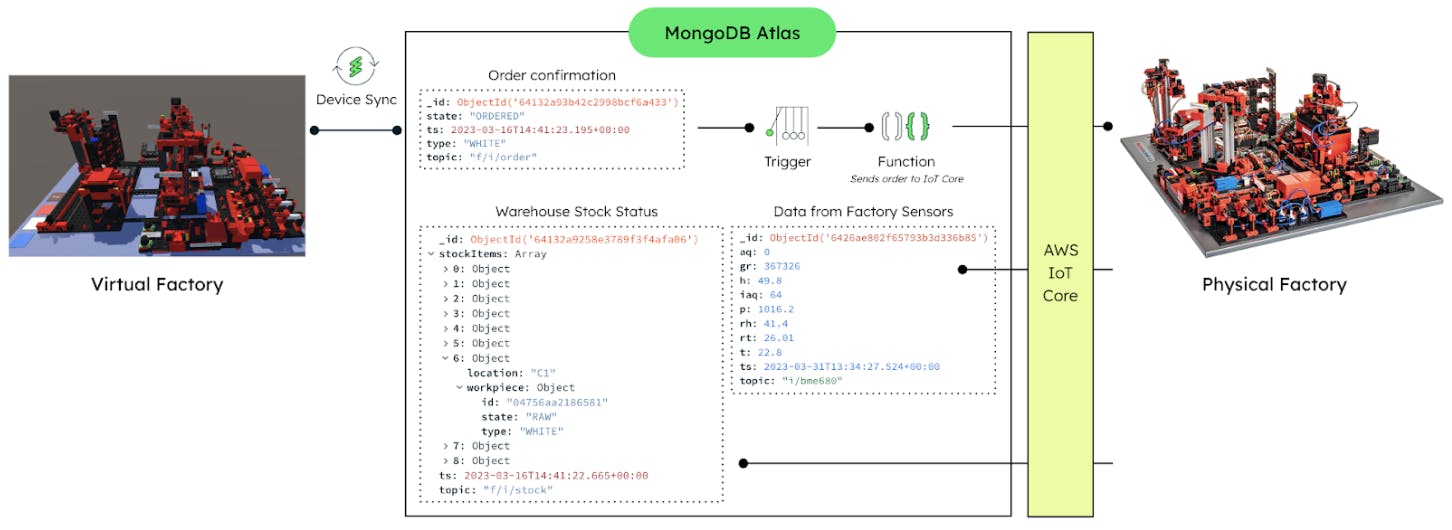

By the end of this demo, you’ll learn how to create a virtual factory in five steps and implement a real-time computer vision inventory inference solution. The focus will be on connecting a physical factory with its digital twin using MongoDB Atlas, which facilitates real-time interaction between the physical and digital realms.

Other Applicable industries and use cases:

Healthcare: In healthcare, digital twins can be used to simulate and optimize hospital workflows, patient care processes, and resource allocation. These simulations can help identify bottlenecks, improve patient outcomes, and enhance overall operational efficiency.

Oil and Gas: In the oil and gas sector, digital twins can be used to simulate drilling operations, optimize oil rig layouts, and predict potential equipment failures. These simulations aid in reducing downtime and maximizing productivity.

Retail: In retail, digital twins can simulate store layouts, customer foot traffic, and product placements. These simulations can help retailers design store layouts that enhance the shopping experience and increase sales.

Reference Architectures

Data model approach

As you may know, any piece of data that can be represented in JSON can be natively stored in and easily retrieved from MongoDB. The MongoDB drivers take care of converting the data to BSON (binary JSON) and back when querying the database. Furthermore, you can use documents to model data in any way you need, whether it is key-value pairs, time-series data, or event data.

MongoDB Time Series collections allow you to automatically store time series data in a highly optimized and compressed format, reducing customer storage footprint, as well as achieving greater query performance at scale.

Building the solution

The principles shown here can be applied to your proprietary hardware so you can run similar workloads. In this case, we are using a Training Factory from Fischertechnik.

1. Set up the Unity Model

Based on the previous business requirements, we created a 3D-model of the factory in a widely used game engine, Unity. This virtual model can be visualized using a computer, tablet, or any virtual reality headset. Download the project from our GitHub repository.

2. Set up the computer vision inference

How do we make the Digital Twin aware of the stock in the warehouse of the Physical Factory so we make it possible to order within Unity? We will have a camera pointing to the warehouse of a physical factory and sending images to MongoDB and Sagemaker to infer the stock of the physical warehouse with Computer Vision. Once we've inferred the stock, we will make the Digital Twin Atlas Device SDK database aware of the state of it thanks to Atlas Device Sync. Follow the steps in our GitHub repository.

Technologies and products used

MongoDB Developer Data Platform

Partner Technologies

Key Considerations

- The importance of using the document model to store the very diverse amounts of data coming from IoT devices, for example with the use of time-series collections

- How MongoDB integrates natively with external services (such as AWS IoT Core and Sagemaker) to provide even more powerful applications

- How companies can reduce costs, and be faster to market with digital twins and MongoDB

- How you can use all the Atlas Device SDKs to implement it almost everywhere (in this case the C# SDK to code Atlas Device SDK in Unity)

Author

- Dr. Humza Akhtar, MongoDB

- Ainhoa Múgica, MongoDB

- Arnaldo Vera, MongoDB

Related resources

Developer Jumpstart: The Virtual Factory

Learn how to bring IoT, visualization, and AI together seamlessly to create a virtual factory.

MongoDB & IIoT: A 4-Step Data Integration

MongoDB’s flexible, highly available, and scalable platform allows for end-to-end data integration using a four-step framework.

Smart Factory Github Repo

Create a smart factory yourself with the sample data, functions, and code.

Real-Time Inventory Tracking

Delve into the technical aspects of implementing a real-time computer vision inventory inference solution.